Worldwide customers: "Glindemann PTFE Sealing Rings"

Please contact Dr. Glindemann at dglinde@aol.com if you currently experience ordering problems.

Home (English) Business: Glindemann Sealing Rings 科技出版物,Dietmar Glindemann

|

News Worldwide customers: "Glindemann PTFE Sealing Rings" Please contact Dr. Glindemann at dglinde@aol.com if you currently experience ordering problems. |

GLINDEMANN®-封闭环![]() (PTFE,聚四氯乙烯制成)

(PTFE,聚四氯乙烯制成)

用于实验室有磨砂渐尖(锥形)接头的玻璃器皿

Dietmar Glindemann

博士, Goettinger Bogen 15, D-06126 Halle,

Germany,

电话 +49-(0)345-6879948,

传真 +49-(0)345-6871333.

电子邮件地址: dglinde@aol.com,

网址 : www.glindemann.net

Links in this site:

批发商及产品目录编号,

Glindemann

封闭环

发送及价格,

Glindemann

封闭环

目的,Glindemann

聚四氯乙烯封闭环

程序 (怎样使用),

Glindemann

封闭环

(使用者)经常问的问题,

Glindemann

封闭环

测试报告

(参考资料),

Glindemann

封闭环

|

(this table needs reconstruction, please use the

English version) 批发商及产品目录编号, GLINDEMANN® 封闭环 (查找在某一国有业务的批发商, 见下表) |

|||||||||||

| 接头最大直径/毫米 | 7 | 10 | 12 | 14 | 19 | 24 | 29 | 34 | 45 | 70 | Distribution in |

| Glindemann 编号 | K7 | K10 | K12 | K14 | K19 | K24 | K29 | K34 | K45 | K70 | |

| 每(销售)单元所含的封闭环数 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

| Aldrich, 敲击联接, 200个国家, 200个地址, 遍布全球 | |||||||||||

| ALDRICH

Sigma-Aldrich China Inc. Shanghai, China Phone: 86 21 6386 2766 Fax: 86 21 6386 3966 E-mail: china@sial.com |

Z501980 | Z502081 | Z502200 | Z502316 | Z502413 | Z502529 |

|

||||

| Distribution in USA, Canada, Mexico by Kimble-Kontes (order is possible from every major labware company such as VWR and Fisher Scientific, Aldrich) | |||||||||||

|

Free samples in USA, Canada:

Call 1-888-546-2531

Kimble-Kontes, ask for Samples Joint Size 24, Catalogue number 676005-2440, or visit Kimble-Kontes at trade shows. |

|||||||||||

| KIMBLE-KONTES USA | 676005-1030 | 676005-1420 | 676005-1922 | 676005-2440 | 676005-2942 | 676005-4550 | America | ||||

| VWR USA | KT 676005-1030 | KT 676005-1420 | KT 676005-1922 | KT 676005-2440 | KT 676005-2942 | KT 676005-4550 | America | ||||

| Fisher Scientific USA |

K 676005-1030 | K 676005-1420 | K 676005-1922 | K 676005-2440 | K 676005-2942 | K 676005-4550 | America | ||||

| Thomas Scientific USA |

676005-1030 | 676005-1420 | 676005-1922 | 676005-2440 | 676005-2942 | 676005-4550 | America | ||||

| ALDRICH | Z50,198-0

(Z501980) |

Z50,208-1 (Z502081) |

Z50,220-0 (Z502200) |

Z50,231-6 (Z502316) |

Z50,241-3 (Z502413 ) |

Z50,252-9 (Z502529) |

America | ||||

| Distribution in Australia and Europe | |||||||||||

| LABGLASS | GSR7 | GSR10 | GSR12 | GSR14 | GSR19 | GSR24 | GSR29 | GSR34 | GSR45 | GSR704 | Australia, Oceania |

| Carl Roth GmbH, link to 8 European countries | T221.1 | E699.1 | E700.1 | E701.1 | E702.1 | T222.1 | Europe | ||||

|

Fisher-Scientific in Germany |

10125930 (3391345) |

10268410 (3391346) |

10228460 (3391347) |

10636521 (3391348) |

10782131 (3391349) |

10646521 (3391350) |

10390001 (3391351) |

10257790 (3391352) |

10686901 (3391353) |

Germany, Austria, Switz. | |

| Merck Eurolab in Germany VWR International Inc |

2016251 | 2016252 | 2016253 | 2016256 | 2016258 | 2016260 | 2016262 | 2016263 | 2016264 | 2016266 | Germany, Austria, Switzerland. |

| Quadrolab (LHU), link to 12 European countries | 9.011 663 | 9.011 664 |

9.011 665 | 9.011 666 | 9.011 667 |

|

|

Europe | |||

| LR. Vetter Laborbedarf e.K. | DKA-7 | DKA-10 | DKA-12 | DKA-14 | DKA-19 | DKA-24 | DKA-29 | DKA-34 | DKA-45 | DKA-70 | Germany |

| AMSI-Glas AG | 6.300.007 | 6.300.010 | 6.300.012 | 06.300.014 | 06.300.019 | 06.300.024 | 06.300.029 | 6.300.0344 | 6.300.045 | 6.300.070 | Switzerland |

|

(this table needs reconstruction, please use the

English version) 个地址, 批发商, 国家, 遍布全球 (产品目录编号, 见上表) |

||||

|

公司 |

地址 |

电话,传真,电子邮件 | 产品目录编号,(见上表) | 批发国 |

| ALDRICH

(since September 2002) Prizes up to 50% higher, but ordering is convenient. Click link to find 200 countries |

ALDRICH |

Worldwide, 200 countries |

||

| Sigma-Aldrich China Inc. | Shanghai, China |

Phone: 86 21 6386 2766 Fax: 86 21 6386 3966 E-mail: china@sial.com |

ALDRICH |

China (中国), |

| Quadrolab in Austria Bartelt , Wagner & Munz Austria |

click link |

click link | Quadrolab | Austria |

| Carl

Roth in Austria LACTAN GesmbH & Co. KG |

Zinzendorfgasse 10-12, A-8011 Graz | Ph: 0316/32 36 92-0 Fx: 0316/38 21 60 Lactan.Labor@aon.at |

Carl Roth (ROTH) | Austria |

|

LABGLASS |

24 Windorah St, Stafford, Brisbane, Queensland, 4053, Australia |

Ph:

++61(0)7-3356 8199 |

LABGLASS | Australia, New Zealand, Oceania |

| Quadrolab in Belgium Devos-Francois S.A. |

480, rue de Châtelet B- 6010 Charleroi, Belgium |

Ph: ++32(0) 71 440870 Fx: ++32(0)71 440890 e-Mail: mail@d-f.be | Quadrolab | Belgium |

| Carl Roth in Czechia - Ceska P-LAB A.S. |

Ricanska 10, CZ-10100 Praha 10 |

Ph: 02/171-380 00, -322 02, Fx: 02/171-311 76, info@p-lab.com | Carl Roth (ROTH) | Czechia - Ceska |

| Quadrolab in Denmark Bie & Berntsen , Buch & Holm |

click link |

click link | Quadrolab | Denmark |

| Quadrolab in Spain Serviquimia s.a. |

Pere IV 29-35, 5° 1°, E-08018 Barcelona, Spain | Ph: 0034 (0)93 3003493, Fx: 0034 (0)93 3003493, serviquimia@serviquimia.com | Quadrolab |

Spain - Espagna - Portugal |

| Carl Roth in

Spain Carl Roth S.L. |

La Jota, 86, E- 08016 Barcelona | Ph: 93-3 52 60 61, Fx: 93-3 49 80 23, carl.roth@retemail.es | Carl Roth (ROTH) |

Spain - Espagna Portugal |

| Carl Roth in France Roth-Sochiel S.A.R.L |

3, rue de la Chapelle/B.P. 11, F-67630 Lauterbourg, France |

Ph: 03 88 94 82 42 Fx: 03 88 54 63 93, sochiel@carlroth.de |

Carl Roth (ROTH) | France |

| Quadrolab in

France Sodipro S.A. |

42, rue Ambroise Croizat, BP 307, F-38434 Echirolles Cedex, France |

Ph: 0033 (0)4 7623 3927, Fx 0033 (0)4 7623 2412, sodipro.38@wanadoo.fr | Quadrolab | France |

| Fisher Scientific Germany | Im Heiligen Feld 17 58239 Schwerte |

Ph++49 (0)2304

/ 932-800 |

Fisher Scientific Germany | Germany, Austria, Switzerland |

| Merck Eurolab (VWR) | John Deere Str. 5, |

Ph++49

(0)7251/717-0 |

Merck Eurolab (VWR) | Germany, Austria, Switzerland |

| Quadrolab (LHU, Omnilab) Germany | Postfach 1416 |

Ph++49(0)2225-948690,

|

Quadrolab | Germany |

| LR. Vetter Laborbedarf e.K. | Herrenberger Str. 5, D-72119 Ammerbuch, Germany | Ph++49(0)7073/6936, Fx++49(0)7073/2740 | Vetter | Germany |

| Carl Roth GmbH, Germany | Schoemperlenstr. 3, D-76185 Karlsruhe, Germany |

Ph++49

(0)721/5606-0, |

Carl Roth (ROTH) | Germany |

| Quadrolab in Italy EXACTA + OPTECH labcenter s.p.a. | click link | click link | Quadrolab | Italy |

| Carl Roth in UK ROTEC SCIENTIFIC LTD. |

10, Bridgeturn Avenue, Old Wolverton, GB-Milton Keynes MK 12 5QL, UK | Ph: 01908 22 33 99, Fx: 01908 22 30 00, Sales@techmate.co.uk |

Carl Roth (ROTH) | Ireland |

| Quadrolab in UK AJ Cope & Son Ltd |

The Oval, Hackney Road, London E2 9DU, UK | Ph: 0044 (0)207 729 2405, Fx: 0044 (0)207 729 2657, cjc@ajcope.co.uk | Quadrolab | Ireland |

| Quadrolab in the Netherlands Boom B.V. |

P.O. Box 37 NL-7940 AA Meppel Rabroekenweg 20 NL- 7942 JE Meppel | Ph: ++31(0)522 268700 Fx: ++31 (0)522 260779 boombv@boomlab.nl | Quadrolab | Netherlands |

|

LABGLASS |

24 Windorah St, Stafford, Brisbane, Queensland, 4053, Australia |

Ph:

++61(0)7-3356 8199 |

LABGLASS | New Zealand, Oceania |

| Quadrolab in Norway INSTRUMENT-TEKNIKK A/S BIOTEST (Member of the Bie & Berntsen-Group0 | Grini Naeringspark 1/PB 14 N-1332 Oesteraas (Oslo) | Ph: ++47 (0)671 49303 Fx: ++47 (0)671

49302 firmapost@instrument-teknikk.no |

Quadrolab | Norway |

| Carl Roth in Poland Linegal Chemicals Sp.z o.o. |

ul. Kasprzaka 44/52, PL-01-224 Warszawa | Ph: 022/632-32 21 w.-33 74,-31

92,-32 91, Fx: 022/631-72 81 |

Carl Roth (ROTH) | Poland - Polska |

| Quadrolab in Sweden Bie & Berntsen, Buch & Holm |

click link | click link | Quadrolab | Sweden |

| AMSI-Glas AG | Lörracherstr. 50, CH-4125 Riehen, Switzerland |

Ph ++41-(0)61-6432626, Fx ++41-(0)61-6432627 | AMSI-Glas AG | Switzerland |

| Carl Roth in UK ROTEC SCIENTIFIC LTD. |

10, Bridgeturn Avenue, Old Wolverton, GB-Milton Keynes MK 12 5QL, UK | Ph: 01908 22 33 99, Fx: 01908 22 30 00, Sales@techmate.co.uk |

Carl Roth (ROTH) | UK |

| Quadrolab in UK AJ Cope & Son Ltd |

The Oval, Hackney Road, London E2 9DU, UK | Ph:++44 (0)207 729 2405, Fx:++44 (0)207 729 2657, cjc@ajcope.co.uk |

Quadrolab | UK |

| KIMBLE-KONTES | 1022 Spruce Street, Vineland, NJ 08360 | Ph ++1-609-692-8500, Fx ++1-609-692-3242 | Kimble-Kontes | USA/Canada/Mexico |

| VWR USA | 1310 Goshen Parkway West Chester, PA 19380, USA |

Ph 1-800-932-5000, Phone: (610)

431-1700 Fax: (610)431-9174 |

VWR USA | USA/Canada/Mexico |

| Fisher-Scientific USA | Fisher Scientific Worldwide, Export Division, 50 Fadem Road, Springfield, NJ 07081-3193, USA |

Phone:

1-973-467-6511, |

Fisher-Scientific USA | USA/Canada/Mexico |

| ALDRICH

(since September 2002) Prizes up to 50% higher, but ordering is convenient. Click link to find 200 countries |

ALDRICH | Worldwide, 200 countries |

||

back to the top

发送及价格,Glindemann

封闭环:

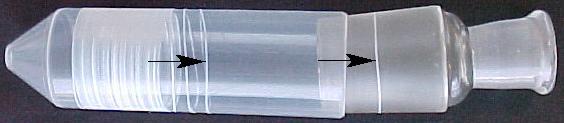

适用于7至70毫米直径的锥形接头.

一个发送单元含:

50个薄膜环,

存放在操作管上.

该管的直径与相应的接头尺寸一样.

放在贴了标签并附有多种语言的说明书的包装袋中.

50 rings on a storage tube

图:

50个聚四氯乙烯封闭环

保存在一个塑料存放管上.

与29毫米接头相配

目的,Glindemann 聚四氯乙烯封闭环

玻璃器皿达到超密闭及超清洁而无须涂加润滑油 一种经济而且意想不到更有效的通常使用的聚四氯乙烯接头套管或塞子的取代物 泄漏程度特别低 空气泄漏率小于10-8 10-6 毫巴*升/秒. 溶剂泄漏率<0.1至 毫克/天. 可用于需要在玻璃容器或仪器中保存的化学物质或样品 环与塑料接头夹钳可配合使用 挑战性的应用: 金属有机化学, 药剂学, 生物化学, 环境化学

back to the top

使用步骤, Glindemann 封闭环

一个发送单元含 50个薄膜环, 存放在操作管上

|

在好的插头上, 该环看上去象涂了润滑油似的"密封" |

慢慢地塞上插头.密封环应整圈看上去透明地"紧贴"于插头上. 不用过于用力挤压,以免损坏接头. 对于比较粗糙的玻璃接头,可以使用微量的润滑油. 还可以通过旋转摩擦塞子来产生聚四氯乙烯小碎屑以润滑玻璃.

拆开接头 逐渐推拉以拆开接头(不要只往外拉). 如果是两个环, 需要多来回几次.

Frequently asked questions and Know How on PTFE sealing rings for Taper Joints

QUESTION: Ordering. Where can I order these PTFE sealing rings? ANSWER: Search the list of traders at this homepage. If your home trader is not on the list ask him to manage to buy sealing rings from one of the listed traders for you.

QUESTION: Sizes. Are sealing rings available for all joint sizes? ANSWER: Yes. Rings are available for 5...70 mm taper diameter.

QUESTION: What is the price of these PTFE sealing rings?

ANSWER: The price is in Europe about 25 Euro per unit of delivery (50 rings). So one ring is about 0,50 Euro.QUESTION: How does the PTFE ring seal working?

ANSWER: The plastic PTFE (known as Teflon) of the sealing ring acts similar to joint grease. But PTFE is much more clean and chemicly inert than joint grease. The PTFE flows under high pressure slowly like grease or wax into the uneven spots of the ground glass surface. By this cold flow the free leakage volume between the 2 joint parts is filled and sealed by PTFE. PTFE is in fact much harder than grease or wax. To make PTFE flowing like grease it must be under a very high pressure. This pressure is produced by pressing the 2 glass joint parts together. But the force to produce this pressure is applied to the PTFE and the glass as well. This force can break the female part of the glass joint by tensile stress. But the glass is of course not allowed to break ever. Therefore, the PTFE ring is shaped to contact the surface of the ground joint only at a very small area (just the area of the 0,6 mm wide ring). If you force the 2 glass joint part together they contact each other only via the small PTFE ring. This relatively small force results therefore in a comparatively large deformation pressure on the PTFE. With this theory on PTFE ring seals in mind you can use the following rules to use these rings more efficient: Any factor which makes the PTFE more soft makes the seal better (high temperature, presence of traces of plasticizers, solvents, water, grease). Any factor which makes the ground glass surface more smooth makes the seal better (polishing of the glass surface). Any factors which gives the PTFE more time to flow makes the seal better (usually the final sealing is better a few hours after pressing the joint together).QUESTION: I have doubts that PTFE can seal a glass joint properly. I used PTFE-sleeves and found they have no sealing properties compared to a bare glass joint.

ANSWER: The common PTFE sleeves which do not have sealing ribs have in fact no sealing effect because they do not work like PTFE rings. PTFE sleeves cover the whole joint. Therefore, the pressure on sleeves is too low to make the PTFE flowing like grease.QUESTION: Sealing Containers. Can I use the PTFE sealing rings to seal containers with glass taper stoppers? (Reagent tubes, flasks, erlenmeyer flasks, bottles)

ANSWER: Definitely, this works great. You fill find, that the PTFE sealing ring will make the glass stopper fixed in the container. Therefore, a slight overpressure in the bottle will not push out the glass stopper. To loosen the glass stopper, do not pull the joint parts apart because this needs too much strength. Instead, move the stopper to and from several times or rotate one joint part.

QUESTION: I can not remove the stopper with a sealing ring from the joint or bottle. Why are the glass joint parts with a sealing ring stuck if I try to pull them apart?

ANSWER: Do not pull the joint parts apart because this needs too much strength. Instead, move the stopper to and from several times or rotate one joint part.QUESTION: Can I use the ring more than one time?

ANSWER: Yes. The ring can be removed from one joint and can be transfered to another joint. But scratches and dirt can make it less tight over the time.

QUESTION: How can I remove the PTFE sealing ring from the glass joint?

ANSWER: Just slip it off. The PTFE rings adheres to the male glass joint just by elastic tension, which prevents the PTFE ring from falling of the male glass joint.

back to the top

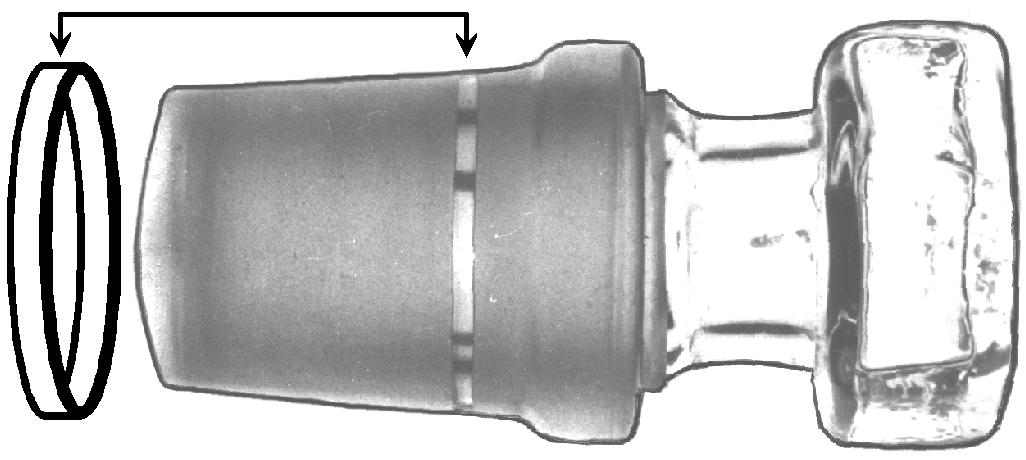

QUESTION: Extra tight seal. I used a PTFE ring seal and found the sealing not proper enough.

ANSWER:

Inspect the seal if it looks transparently "tight" all around the joint. If there are "bad" looking spots (one millimeter is enough to cause leakage) then the ring is probably scratched or dented.

Some times the surface of the ground joint is simply to rough to fit the PTFE ring seal.

There are different possibilities to smooth out the roughness of ground jointed glass ware.

The joint with a PTFE ring seal can be rotated and rubbed to produce microscopic PTFE-particles which smooth the glass at the PTFE-contact zone forever. This zone of the joint looks like greased but it is in fact a layer of small PTFE particles which fill out the uneveness of the ground glass. To make the smooth contact zone broader move the PTFE ring on the joint and rotate the joint parts again. Remove larger visible PTFE-fibres after this procedure. The PTFE-ring used for rubbing has to be sacrificed often because it looses larger PTFE-particles which make the ring uneven.

Foto:

Extra tight seal.

Smooth a 2 mm zone of the male glass joint with PTFE filings from a ring by rubbing. Sacrifice this ring used for rubbing. Slip a new PTFE Ring onto the smoothed zone. This extra smoothing will result in an almost hermetic extra tight seal.

But you can of course use PTFE sealing rings without this procedure, for most purposes.

Another possibility is to soften the PTFE sealing ring. This can be performed by applying a micro scale amount of grease or solvent or water.Do not clean your jointed glass in Potassium Hydroxide solution which makes ground glass even more rough. You can also ask your glass blower for slightly polishing the joints. A simple home made fire polishing procedure is to direct a very hot welding flame (more than 2000oC) for a few seconds (do not deform the joint) directly around the grounded glass surface.

back to the top

QUESTION: Extra clean work: How can I extra clean the PTFE ring for ultra clean work (biochemical, pharmaceutical, analytical, organometal work) ?

ANSWER: You can either bake the ring or you can extract contamination with solvents.

Baking: The PTFE ring can be baked at 300 oC in an oven. But do NOT put the plastic storage tube at heat over 100 oC! Slip the PTFE ring on a male glass taper stopper to prevent it from shrinking .

Solvent extraction: You can bathe, purge or rinse the PTFE rings with any useful solvent (PTFE takes any organic solvent). You can also put many PTFE sealing rings alltogether in a Soxhlet Extractor and rinse them with the solvent, which has a boiling temperature below 70 oC (at higher temperature, the rings will start to shrink).

Take care, that this cleaning (baking or solvent rinsing) will make the PTFE less soft and reduce the sealing power slightly. If you want to soften the PTFE ring again, you can add a micro amount of any greasy, oily or slippery chemical which does not harm your laboratory work.

QUESTION: How can I prevent that the sealing ring teared up and fell off the joint after baking/heating over 200 oC?

ANSWER: Slip the ring before heating on the thinner part of the taper joint.QUESTION: I took the ring off the joint and it contracted to be too small to install it again on a taper joint.

ANSWER: You can stretch the ring to fit again the joint. Stretch the ring with a storage cone which you bought together with the rings from your trader. You can also use two fingers, sticks, nails etc.

Foto:

Sealing ring contracts (shrinks)

if removed from the joint.

QUESTION: The sealing ring became to large in diameter and fell off the joint.

1. Test report of GLINDEMANN-PTFE-sealing rings for ground tapered joints

ANSWER: The diameter of the ring can be decreased by use of high temperature of 100...300 oC (oven, lighter, Bunsen burner).

from: Dr. Andreas Bolte, Group Prof. Dr. Borislav Bogdanivic, Max-Planck-Institute of Coal-Research, Germany

Dear Dr. Glindemann:

Our inorganic and organometallic laboratory research needs often absolute clean and tight sealing of tapered joints on glass equipment.

Your PTFE-sealing rings proved to be a success while:

long term sealing of high vacuum equipment,

long term sealing of inert equipment until 200oC,

sealing of equipment and containers for synthesis and storage of dangerous (inflammable in air), oxygen sensitive and moisture sensitive chemicals,

sealing of equipment where contamination of reaction mixtures by joint grease has to be avoided.

Our group has gone over to use Glindemann-sealing rings instead of joint grease or PTFE-sleeves because of the amazing sealing properties and the advantages of working with greaseless joints.

(some extended information in the German version is not translated here)

We consider your PTFE-sealing rings as the present most advantageous way to work with greaseless and tight joints.

(signed by Andreas Bolte) 2. Test report of GLINDEMANN-PTFE-sealing rings for ground tapered joints

from: Professor Michael D. Fryzuk, Department of Chemistry, University of British Columbia, Canada

Dear Dr. Glindemann:

Thank you for the sample of your amazing o-ring seals. We have used Teflon sleeves in the past for certain situations but we have discontinued this practice because they are too expensive and not particularly effective. We have tested your o-ring seals using an extremely air-sensitive solution of {Co2TiCl}2ZnCl2 in toluene. This material is our indicator for O2 in our inert-atmosphere glove boxes since it goes from deep blue green to bright orange in the presence of 5 ppm of O2. A tube with 3 mL of this deep blue green solution was sealed with a stopper that had one of your seals and no grease inside an inert atmospheres glove box; the tube was then removed to the outside and inverted so that the solution was on top of the stopper. The colour could be seen to penetrate to the o-ring seal and no further. And amazingly, the solution remained blue green for many days. This tells me convincingly that this seal is airtight and robust. I would buy such a product because it is ideal for our research on air- and moisture-sensitive organometallic complex compounds.

Sincerely,

M. D. Fryzuk

for <dglinde@chem.ubc.ca>; Tue, 10 Mar 1998 08:47:40 -0800

back to the top

Links on laboratory glass ware in the internet and to www.glindemann.net:

(If You would like your scientific glass web site mentioned on this page just e-mail me at dglinde@aol.com)

Scientific Glassblowing Societies

American Scientific Glassblowers Society

Belgische en Nederlandse Vereniging voor Glastechniek

British Society of Scientific Glassblowers

German Scientific Glassblowers

Leidse Instrumentmakers School

Scientific Glassblowers Association of Australia and New Zealand

Scottish Glass Society

Vereinigung Österreichischer Glasbläser

Other Glass Links

Scientific Glassblowing Basics (East Carolina University)

Glassblowing Workshop of António Morais, University of Aveiro, PORTUGAL

www.glassline.net/links/ links.html

www.glassonline.com/

www.glassartists.org

back to the top

Disclaimer

The author assumes no responsibility or liability for action resulting from use of this information.